- Threading pipe

- Shisha pipe

- Shrinking pipe

- Electrical corrugated conduit pipe

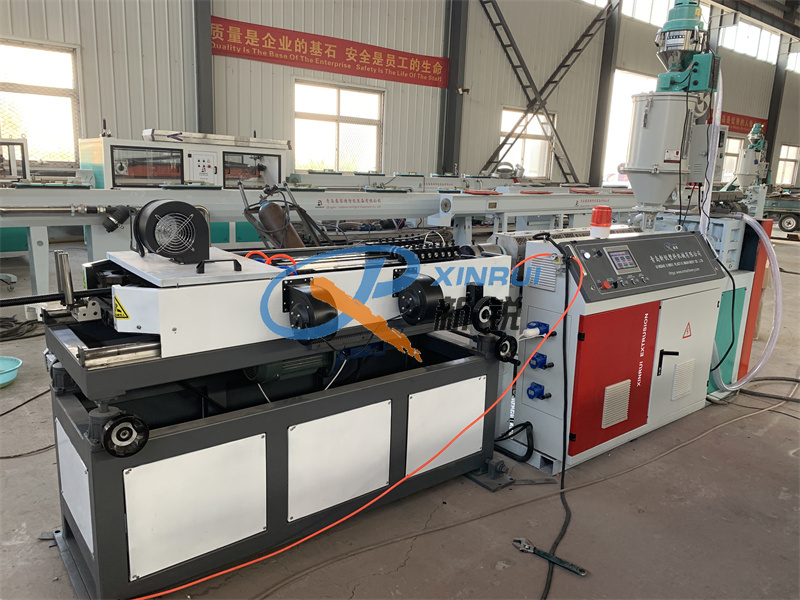

This machine is used to produce pvc pe pp single wall corugated pipe. It can be used such as threading pipe, drain pipe, Shisha pipe, shrinking pipe and so on.Single wall corrugated pipes, which takes the advantages of high temperature resistance, abrasion resistance, corrosion resistance, high strength.The forming machine has closed structure, and we can also provide vacuum forming platform.Forming mould can move back and forth in a closed and integrally tunnel. Forming tunnel is sandwich design and cooling the mould forcedly by cooling water. Molding strip is made of carbide steel, so it is corrosion resistant. It adopts gears to run modules and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall.

Machine description:

Single-wall corrugated pipe machine developed by our company adopts gears to run modules and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding, even corrugation,smooth inner and outer pipe wall. These corrugated pipes are especially used in wires conduit pipe.It is mainly for the production of raw materials to PVC.PP.PE small diameter single wall corrugated pipe. Die by the corresponding forming a homogeneous single-wallcorrugated bellows products. Threading pipe for wire and cable, washing machinedrains, vacuum cleaners, ventilation pipe, prestressed concrete special tubes.

| Model Name | SJ-45/30 | SJ-65/30 | SJ-75/30 |

| Module logarithm | 42 | 56/72 | 56/72 |

| Production pipe diameter range | Φ4-13mm | Φ16-63mm | Φ50-160mm |

| Production speed | 5-15M/Min | 8-25M/Min | 15-32M/Min |

| Production capacity | 30-40Kg/h | 70-80Kg/h | 80-100Kg/h |

Q1: Your company is a trading company or a machine manufacturer?

A1:Our company is a plastic machinery manufacturer which is engaged into this trade more than 15 years.As a manufacturer,we could supply our machine,service,technical support and maintenance directly and it’s more convenient.

Q2: How to get an accurate offer?

A2: Because our offer and technical specification is associated with your final product and requested capacity,we will choose the right model of extruder and mould after understanding all the information,then we could supply our plan.We could fully exchange information by Email, whatsapp or wechat.

Q3: Where is your factory and which port is the nearest to your factory?

A3: My factory is in Qingdao city, Shandong Province and the nearest seaport is Qingdao port.

A4: Generally it will take 30-45 days.

A5: Yes,we will send our engineers to your factory for installation,commissioning and training after machines arrive at your

factory.In addition,if you need our engineers available in the future,we also could send our engineers.If you have any questions, please do not hesitate to contact us. We Look forward to listening to you!

Now start your business!

Supply Reliable Turn-key Project Solution of Plastic Extrusion