Mixer → Extruder → Mould → Calibration Platform → Haul off machine → Cutting Mchine → Robot

2.Extrusion die adopts P20 material which is of higher strength,longer service time and easier operation than traditional die material.

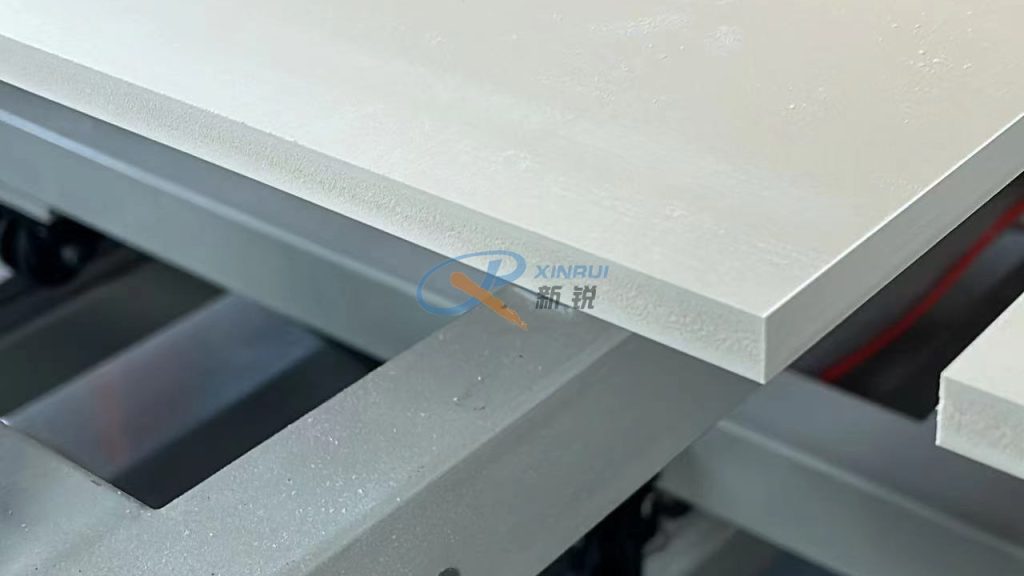

3.Calibration cooling platform is with superior cooling effect which could improve the crust quality.

4.Board surface treatment could be laminated,heat transferred,printed and UV coated.

5.This production line is equipped with all requested auxiliary machines as mixer,pulverizer,crusher,chiller,mould temperature controller,dust collector and so on.

6.High quality electrical components and optimized electric design could ensure stable production and low maintenance.