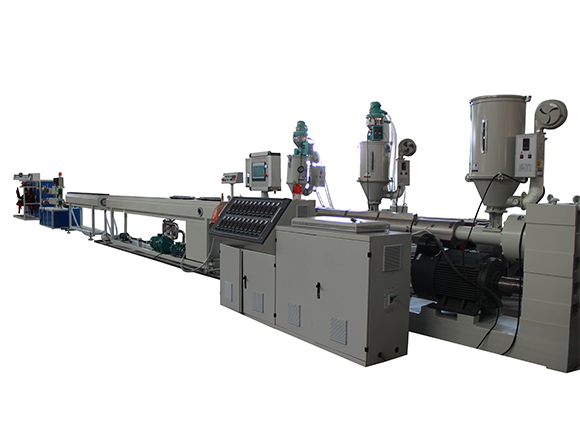

PP PE pipe extrusion line is mainly used in the production of pressure water pipes, agriculture irrigation, building or city drainage and sewage and constructional plumbing cable laying etc.

The unit consists of single screw extruder, pipe extrusion mould, vacuum calibration tank, haul-off machine, cutting machine, Winding Machine

Producing pipe diameter range: Φ20mm-Φ450mm

And the line can be equipped with comptroller thickening instrument, computer ink-jet printer, crusher, shredder, pulverizer, water chiller, air compressor etc.

To achieve the production and manufacture of high-grade tubing.

| Pipe Diameter (mm) | Extruder Type | Extrusion Power (KW) | Max.Capacity (KG/H) | Max.Haul Off Speed (m/min.) |

| Φ20-63 | SJ60/38 | 70 | 320 | 30 |

| Φ20-110 | SJ 60/38 | 90 | 380 | 20 |

| Φ40-160 | SJ 60/38 | 110 | 460 | 15 |

| Φ50-250 | SJ 75/38 | 160 | 600 | 12 |

| Φ110-450 | SJ 90/38 | 250 | 850 | 8 |